Get in Touch with us

- 36-1-A Abhishek Complex, B Wing, 38A, Opp. Bank Of Baroda, GIDC Makarpura, Vadodara- 390010, Gujarat, India

- (+91) 9638370219

- pradeep@vekslerindia.com

- jai@vekslerindia.com

- sales@vekslerindia.com

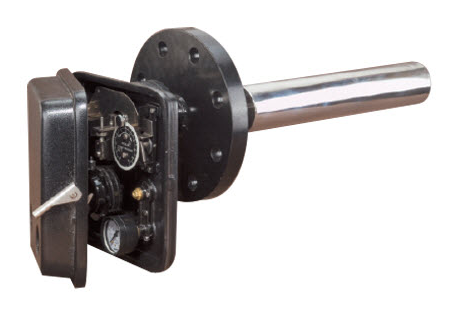

The Interface Level Controller consists of a nozzle, flapper and an amplifying relay which operate on dry air supply or gas. It also has a displacer mounted to the flex tube which is attached to a standard flange. A carrier assembly is mounted on the reverse side of the flange with adjusting screw, nozzle and relay with an orifice. A cleaning device is also provided to clean clogged orifice. The flex tube permits vertical motion only and transmits the displacer motion from within the shaft to the nozzle. The displacer is speciallt designed to sence Specific Gravity difference of even 0.05.

Like most of the level instruments, Liquid interface controller also works on the buoyancy principle. The force applied by the float/displacer is proportional to the volume of liquid displaced. Change in the liquid level causes a change in the position of flex tube end. This causes movement of the flex tube shaft and aflapper is connected to the shaft. A booster relay placed to control the speed and response time helps to remove heavier liquid (Water at a fast speed. The relay is enclosed in a pressure light housing that allows remole release of vented gases and also protects the pilot and pressure gauges from the field disturbances and during cleaning. It operates pneumatically in direct as well as reverse direction. Reverse action can be obtained by rotating the nozzle assembly by 180°.

| Connection | 4" NB CS, ASTMA 105 Flange as standard in 150 #, 300 #, 600 # |

| Enclosure | Die-Cast Alluminium, weather proof to IP 65 |

| Displacer Options | Vertical (Stainless Steel) 76mm OD x 355mm length |

| Vertical (PP) 90mm OD x 115mm length | |

| Horizontal (Stainless Steel) 76mm OD x 440mm length | |

| Differential | Horizontal (Stainless Steel) 76mm OD x 440mm length |

| Vertical (PP float): 20 ± 5mm S.G. difference of 0.1 | |

| Horizontal (SS float): 7 ± 3mm for S.G. difference of 0.1 | |

| 20 mm depending on size of displacer & S.G (Vertical Float) | |

| Inlet & Outlet connection | ¼" NPT |

| Exhaust | Screwed vent connection |

| Max Working Pressure | 60Bar / 60Kg / cm² |

| Temperature | 150 Deg C with Stainless Steel Float & 100 Deg with Phenolic Float |

| Operating Pressure | 1.4 kg/cm², 3 kg / cm², higher on request |

| Mode of Operation | Pneumatic, On-off Direct or Reverse |

| Consumption of Air | 15 CFH (min) to 35 CFH |