PNEUMATIC LEVEL CONTROLLERS

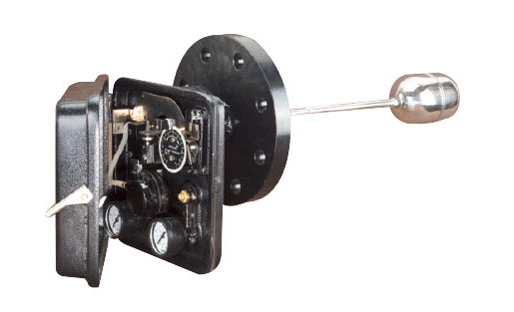

PNEUMATIC LEVEL CONTROLLER (Pneumatic Controller) works on the buoyancy principle. The force applied is proportional to the volume of liquid displaced. Change in the liquid level produces a change in the position of flex tube end. This causes movement of the flex tube shaft to which carrier assembly is connected. Carrier assembly opens or closes the nozzle to give pneumatic output from the pilot valve.

Pneumatic Level Controller consists of a displacer, mounted to the flex tube. The Pilot Valve and carrier assembly are housed in weather proof IP65 housing. The exhaust gas is vented inside the enclosure and then to the atmosphere through a vent hole. The instrument is known for its simplicity, reliability and ease of maintenance. Reverse action can be obtained Nozzle assembly by 180°.

Pneumatic Level controllers Specifications

| Connection | 4" NB CS, ASTMA 105 Flange as standard in 150 # , 300 # , 600 # | |

| Enclosure | Die Cast Alluminium, weather proof to IP 65 | |

| Flex Tube Material | SS 304 / SS 316 / SS 410 | |

| Displacer Options | Vertical (S.Steel) 75mm x 355 mm Long (+ 2mm) | |

| Vertical (S.Steel) 42mm x 200 mm Long (+ 2mm) | ||

| Vertical (Phenolic) 90mm x 115 mm Long (+ 2mm) | ||

| Horizontal (S.Steel) 75mm x 152mm Long (+2mm) | ||

| Differential | 10 to 30 mm depending on size of displacerr & S.G. (Horizontal Float) | |

| Visibility | approx 150 mm less than the CC distance³ | |

| 20 mm depending on size of displacer & S.G (Vertical Float) | ||

| Inlet & Outlet connection | ¼" NPT | |

| Exhaust | Screwed vent connection | |

| Max Working Pressure | 60Bar / 60Kg / cm2 | |

| Temperature | 150 Deg C with Stainless Steel Float & 100 Deg with Phenolic Float | |

| 70 Deg with Acrylic / PP float | ||

| Supply Pressure | 1.4 Kg/cm2, 3 Kg/ cm2 | |

| Output | 0.2 1Kg/cm2, 3Kg/cm2, higher on request | |

| Mode of Operation | Pneumatic, On-off Direct or Reverse |

We are the preferred manufacturers of Pneumatic Level Controllers. We manufacture Pneumatic Level Controllers, Pneumatic Flow Control Valves, Pneumatic Controllers, Pneumatic Control Valves etc.

Contact us for your requirements.

Get in Touch with us

- 36-1-A Abhishek Complex, B Wing, 38A, Opp. Bank Of Baroda, GIDC Makarpura, Vadodara- 390010, Gujarat, India

- (+91) 9638370219

- veksler2007@gmail.com

- pradeep@vekslerindia.com